————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

RELIABLE CLEANING UNDER EXTREME CONDITIONS

Because of size and materials used, cutting and cutting-off also belong to the typical work operations such as cleaning, decoating and derusting. The widest variety of methods and devices have been used up to now for these – requiring considerable investment and logistics. The water jet method is winning through increasingly as the only process to fulfil all these tasks using a single technology. Water used as jetting and cutting means is unbjectionable, in terms of both safety and ecology. The well-proven PINFL plunger pumps and a complete range of devices and tools specially developed for the highest pressures are available for this process.

Cleaning and Maintenance Offshore

- A large variety of materials must be cleaned, derusted, decoated and cut under the most extreme conditions and in a very confined space.

General parts and surface cleaning

- Widely different surfaces and materials must be cleaned regularly so that continuous processes and safety are ensured during operation.

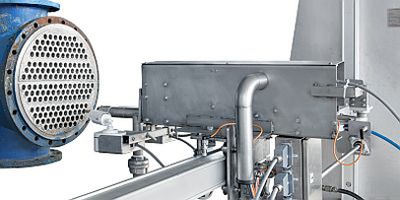

Sieve and filter cleaning

- The functional capability of strainers and filters depends essentially on the state of their surfaces. They must therefore be constantly cleaned.